Unknown Facts About American Plastics

Table of ContentsThe 30-Second Trick For American PlasticsThe 15-Second Trick For American PlasticsSome Of American PlasticsThe Only Guide for American PlasticsNot known Factual Statements About American Plastics

This factor to consider is especially essential for applications that entail high-pressure liquids. The scale and scope of the project likewise play a substantial role in size choice. Bigger jobs may need pipes with greater diameters to efficiently distribute fluids over fars away. Variables such as surface trouble, the capacity for environmental anxiety, and the setup atmosphere ought to affect the pipeline size to ensure an effective, long-term application.

Involve with expert suggestions to verify your choice and adapt as required for ideal results. Armed with this knowledge and the actionable actions described, you are well-appointed to make educated choices when picking HDPE pipeline sizes for your projects. Your attention to information in this choice process will go a lengthy method in making certain the performance, security, and cost-effectiveness of your piping systems.

About American Plastics

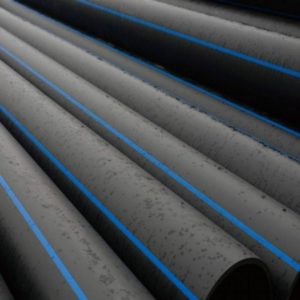

Due to the fact that HDPE is lightweight and chemically inert, it can manage liquid and gas transportation with marginal upkeep. HDPE pipes are commonly taken on throughout a series of markets due to their adaptability and stamina. Among the most typical uses for HDPE pipe remains in water system systems. HDPE's corrosion resistance makes it ideal for both potable and non-potable water distribution, whether in community networks or exclusive systems.

: HDPE pipelines are signed up with via heat blend, creating a smooth, uniform connection as strong as the pipe itself. This leak-proof joint is essential in gas and water distribution, where leaks can cause unsafe scenarios or expensive waste.: HDPE pipelines are lighter than typical metal pipelines, making them much easier to deliver and install.

We have warehouses in several areas to guarantee a quick response. You can obtain in-depth item info and quotes through our official website, by phone, or by email. Our basic and fast buying process and reliable logistics guarantee you obtain your 4-inch HDPE pipeline in the shortest possible time. Our after-sales team is readily available 24/7 to assist with any kind of concerns you might encounter, guaranteeing comfort.

As an example, PE 80 is for easy commercial applications like gas and water, while PE 100 uses lasting strength and efficiency for harder uses. For a succinct take a look at applications, below are a few of one of the most usual kinds of HDPE piping and their applications. Piping systems use PE 32 or PE 40 for low-pressure applications.

An Unbiased View of American Plastics

PE 80 has a product resistant to fractures, so it appropriates in applications vulnerable to splitting, like sewage systems and water distribution lines. PE 100 is likewise immune to fractures, and 100 N/mm2 is the minimum needed strength. As mentioned, classifications of HDPE piping include nominal stress, product, and shade coding.

Producers create pipelines with various pressure grades (PN qualities). This reveals the stress in bars the see here pipeline can sustain with water at 68 degrees Fahrenheit. The pressure qualities adhere to European requirements, and they are: PN 2.5 max pressure 2.5 bar PN 4max pressure 4 bar PN 6max pressure 6 bar PN 10max stress 10 bar PN 16max stress 16 bar The color codes that indicate the stress quality are yellow for PN4, red for PN6, blue for PN10, and environment-friendly for PN16.

Pipeline providers provide sizing guides with extra information like wall surface density and mass. Quality control complies with ISO standards regulating the product design and minimum needed strength (MRS) of pipes.

Industries consider small pressure, material, and various other components when determining which pipes to use - https://old.bitchute.com/channel/07TsFedB01Ik/. Today, you'll see high-density polyethylene pipelines in water supply, gas circulation, agriculture, and much a lot more.

American Plastics for Beginners

It's worth keeping in mind that gas requires high tolerance to pressure, making PN-16 to PN-2 grade pipelines ideal for operations. The agriculture industry makes use of HDPE pipes for watering and drain.

Mining business make use of pipelines for slurry transportation and dewatering. HDPE piping can safeguard wires in the telecommunications market. This is advantageous for below ground cords. The very best part is that companies can make use of basic PN class pipelines for this application. Industries select HDPE piping over conventional pipelines since they provide more advantages.

For starters, HDPE pipelines are incredibly durable and can last a lengthy time with minimal upkeep. HDPE pipes are lighter than conventional pipelines for much better handling and transport.

A Biased View of American Plastics

Whether you're a contractor, designer, or do it yourself fanatic, this post will certainly provide you with the understanding to make informed choices and achieve optimum outcomes. When it involves choosing the appropriate HDPE pipe for your job, understanding the PSI rating is of utmost significance. The PSI rating gauges the toughness and pressure capability of the pipe, suggesting just how much pressure it can withstand without failing.

The PSI rating of an HDPE pipeline determines its ability to handle various pressure levels. Pipes with greater PSI rankings can endure better pressure, making them ideal for applications that involve greater fluid or gas stress. On the various other hand, pipes with reduced PSI scores are optimal for low-pressure applications.